What to Consider When Choosing and Sourcing Vaping Hardware?

- Share

- Issue Time

- Apr 10,2023

Summary

With a wide range of cannabis vaping suppliers out there, it’s difficult to tell which companies can consistently deliver safe, and compliant vape products.

To create a safe, reliable, and enjoyable vaping experience, it's crucial to guarantee safety throughout the whole manufacturing process. When choosing and sourcing vaping hardware suppliers, there are top 4 things you should consider: quality raw materials, design, supply chain management, and strict quality control.

Within

the vaping hardware industry, raw material control is an important part of

quality assurance. High quality vape hardware can be produced only from high

quality raw materials. Core components including ceramic components, connecting

rod, 510 connector, glass tank, mouthpieces, etc. must meet not only customers’

demands but also regulatory requirements. For example, stainless steel is

widely used in vape cartridges because oil cannot leech harmful toxins from corrosion-resistant metal.

Jamie

Rosen, CEO and founder of Las Vegas-based Dr. Dabber, a CBD vaporizer company,

talked about the topic of HOW TO SOURCE AND SELECT VAPE HARDWARE recently. He

mentioned that steel is the easiest material to work with and steel is

relatively easy to machine, can be made in all shapes, and fitted together with

a wide range of other components. Stainless steel also can be a medical grade for

use in vape products and contact with concentrates.

Furthermore,

the core components including metals, ceramics, plastics, glass, batteries, etc. could be provided from different suppliers. Control of raw materials

should be developed with suppliers and the whole supply chain, not only in the

manufacturing factories but also with raw material suppliers. Guidelines for safe

packaging of raw materials, and finished products, and standard operating procedures

should be followed strictly.

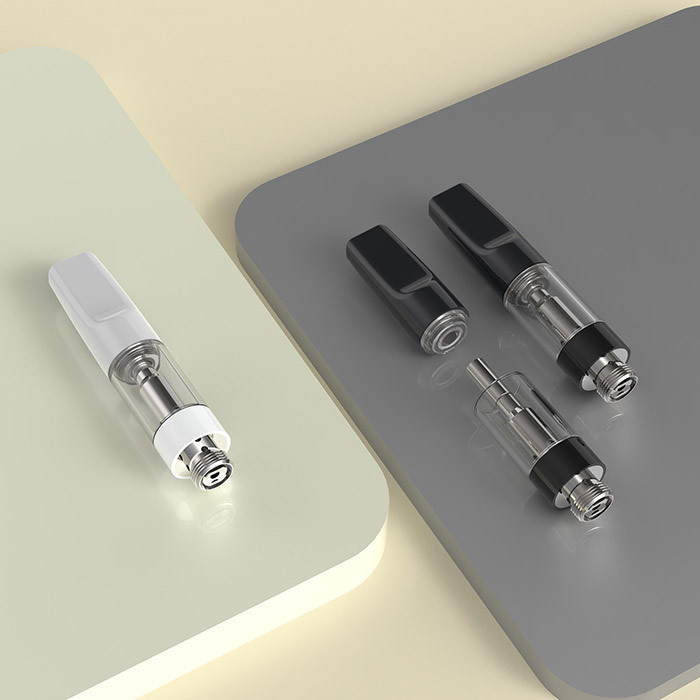

Ease

of use, anti-leak structure, quality experience, customization, and other

aspects are key considerations when we develop new products. Some vape pens

allow the user to adjust the voltage allowing for a more customized experience

while others have been developed with a constant voltage to get a nice amount

of vapor and good flavor directly.

Custom

vape carts and vape pens provide the creative edge of a beautifully branded

vape product that will stand out among the crowd of generic unbranded products.

An

optimized supply chain helps in predicting and meeting customer demand and

helps with transparency and traceability to help boost vape hardware quality

and safety.

In

the rapidly expanding cannabis industry, a strong, sustainable supply chain and

steady manufacturing will help you maintain a greater competitive advantage.

Our

goal is to maintain steady manufacturing for all regular and new customers. At

the beginning of the year 2020, to avoid long-term or short-term supply

shortages, Transpring stocked six months of supply because the battery life on

many disposable vapes is typically six months. Thus, it gives us more time to

manage risk or adapt quickly to change.

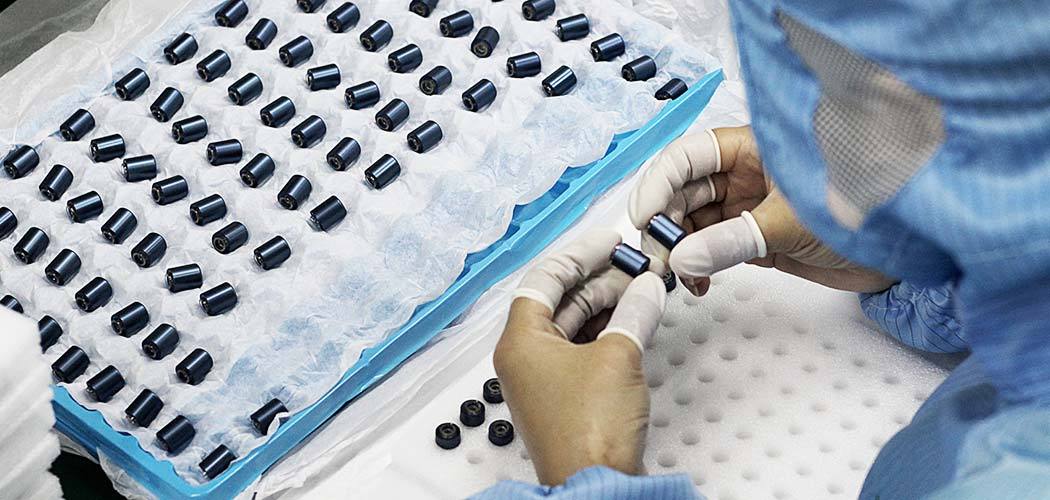

Quality

control is one of the most important procedures for vape hardware business.

Strict quality control should be performed throughout the whole manufacturing

process.

Transpring

upholds the highest quality standards in the vape industry because Transpring’s

manufacturing facilities are GMP compliant, ISO9001 and ISO 13485 certified,

utilize dust-free facilities, and products are lab tested. Good practices were

created by performing quality audits in different sectors of the factory,

adopting quality systems across the supply chain, and implementing programs for oil producers in the past years.

With

the goal of continuously improving quality, we made every effort in quality

management, including managing the supply chain, updating knowledge for product

safety, measuring customers’ satisfaction, and training quality control personnel.

For

example, quality control personnel play an important role in the quality

control systems and they’re required to be qualified in each processing area.

They also collect samples for the performance evaluation process, and unit

operations, verifying compliance with the requirements of vaping hardware

safety, and other processes. As a GMP-certified facility, Transpring’s

dust-free workshops set the strictest rules of personal hygiene and cleanliness

of the workplace.

Cheaper

vape hardware can break, leak, and even worse. It’s vital to focus on quality in

the process of raw material selection, design, supply chain management, and

strict quality control.

Oil

manufacturers make the perfect oil and we offer hardware to make customers an enjoyable vaping experience.