Cannabis Vape Hardware Breakdown: What Is The Heating Element

- Share

- Issue Time

- Sep 26,2025

Summary

This article breaks down the concept of the heating element in cannabis vape hardware: what it is, how it works, and why it matters so much.

Introduction

In the cannabis vape industry, many terms get thrown around when people talk about performance, flavor, or longevity. One of the most important—but sometimes least understood—components is the heating element. Without it, there is no vaporization, no flavor, and no experience. Yet, the design and material of the heating element determine everything from taste to safety to how well a cartridge can handle different cannabis extracts like rosin, resin, or distillate.

This article breaks down the concept of the heating element in cannabis vape hardware: what it is, how it works, and why it matters so much.

What Is the Heating Element in a Vape?

At its core, a cannabis vape pen is a simple device: it contains a battery, a tank filled with cannabis oil, and a mechanism to turn that oil into inhalable vapor. The heating element is the part responsible for this transformation.

In technical terms, the heating element is the component inside the vape that converts electrical energy into heat energy. Once it reaches the right temperature, it vaporizes the cannabis oil into a fine mist that users inhale.

When users talk about “smooth flavor,” “big clouds,” or “consistent hits,” they are actually evaluating the performance of the heating element. If the heating element is poorly designed or uses unsuitable materials, problems arise—burnt taste, clogging, leaking, or even failure to produce vapor.

In the cannabis vape world, heating elements have evolved significantly. Early devices often used metallic coils or cotton wicks, but over time, ceramic-based heating elements became the industry benchmark. Ceramic cores distribute heat more evenly, preserve delicate terpenes, and withstand the demands of thicker cannabis extracts

How Does a Heating Element Work?

The basic science behind a heating element involves electrical resistance.

1. Electrical Current: When the user activates the vape, the battery sends an electric current to the heating element.

2. Resistance Heating: The heating material—often a metal wire, alloy, or embedded conductor inside ceramic—resists the flow of electricity. This resistance causes it to heat up.

3. Heat Transfer: The heat generated transfers to the surface area of the element, which comes in direct contact with the cannabis oil or indirectly through a porous medium.

4. Vaporization: Once the oil reaches its vaporization temperature (typically between 160°C and 230°C, depending on compounds), it changes from liquid into inhalable vapor.

The exact design of the heating element affects every step in this process:

- Material: Metals like Kanthal, stainless steel, or nichrome were common in early vapes. Today, ceramic is preferred because it provides stability and neutral flavor.

- Structure: Whether the element is a coil wrapped around cotton, a porous ceramic rod, or an advanced sintered ceramic core, the structure determines how well the oil is absorbed and vaporized.

- Temperature Control: Modern technology allows precise regulation of temperature curves, preventing burning while optimizing terpene release.

When done right, the heating element works in harmony with the oil to deliver consistent, flavorful puffs. When done poorly, it can lead to overheating, degradation of cannabinoids, or harmful by-products.

Types of Heating Elements in Cannabis Vapes

To better understand the role of the heating element, let’s look at the common designs in the cannabis vape industry:

1. Metal Coil with Cotton Wick

- Description: A metal coil (often nichrome or stainless steel) is wrapped around a cotton wick that absorbs cannabis oil.

- Pros: Simple design, low cost, quick heating.

- Cons: Prone to burning, inconsistent heating, flavor degradation, and not suitable for thicker oils.

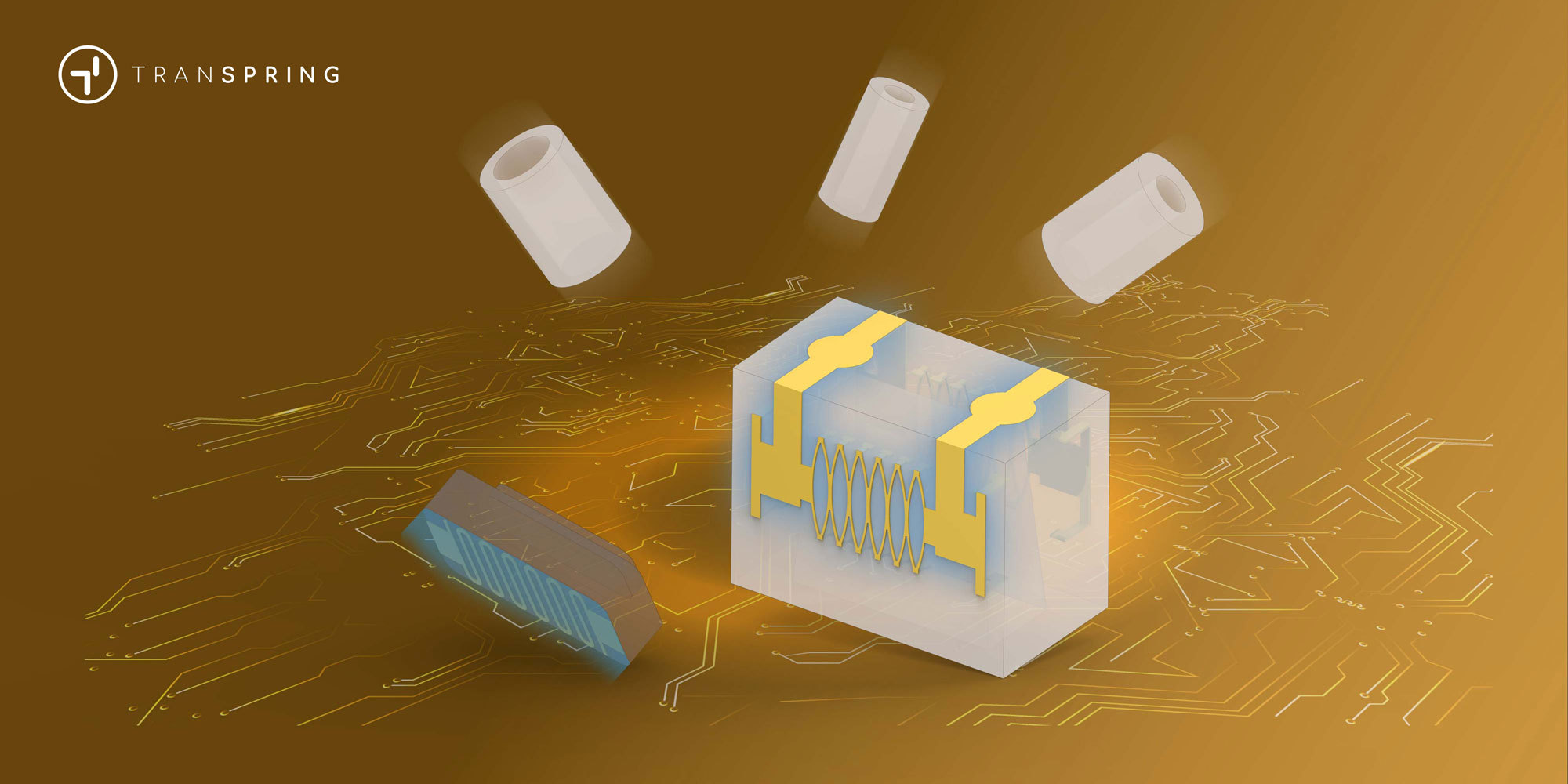

2. Porous Ceramic with Embedded Heating Wire

- Description: A ceramic rod with a wire heating coil inside. Oil is absorbed into the ceramic pores and vaporized by the internal heat.

- Pros: Better heat distribution, improved flavor preservation, longer lifespan.

- Cons: Still dependent on the quality of embedded wires and ceramic formula.

3. Full Ceramic Core (Vape Without Cotton)

- Description: A sintered ceramic structure acts both as oil absorber and heater, with conductive materials integrated during manufacturing.

- Pros: Superior flavor retention, resistance to burning, compatibility with high-viscosity cannabis oils, and no cotton contamination.

- Cons: More complex manufacturing, requiring precise ceramic formulas and sintering processes.

Among these, full ceramic cores have become the industry’s premium choice, especially for cannabis extracts like rosin and resin that demand precise and clean heating.

Transpring’s Ceramic Heating Elements

In the fast-growing cannabis vape industry, many companies rely on outsourced or generic heating element designs. Transpring chose a different path. From the moment we transitioned into ceramic core technology, we committed to independent research, development, and manufacturing of our own ceramic heating elements.

In-House Ceramic Core Factory

Unlike many competitors, Transpring operates its own ceramic core production facilities. This allows us to control every detail of the process—from raw material formulas to structural engineering and sintering. Having an in-house factory ensures consistency, reliability, and room for innovation.

Custom Ceramic Formulas

Ceramic performance depends heavily on the composition of its raw materials. Transpring has developed proprietary ceramic formulas to balance porosity, heat conductivity, and durability. These formulas enable our cores to deliver smooth, full-bodied vapor while resisting cracks and clogging.

Precision Structural Design

We understand that cannabis extracts are not all the same. Distillates, resins, and solventless products each behave differently under heat. That’s why Transpring designs multiple structural variations of ceramic cores, ensuring compatibility across different oil types and market demands.

Advanced Sintering Process

The sintering process—where ceramic material is heated at high temperatures to fuse particles together—directly impacts porosity and strength. Transpring has refined sintering techniques to achieve the perfect balance of absorption and durability, giving our heating elements both resilience and precision performance.

Market-Driven Solutions

Through years of R&D, we have studied countless ceramic core configurations, matching them to specific cannabis oil requirements. Whether it’s maximizing terpene expression for rosin, preventing leaks in thinner distillates, or ensuring long-lasting stability in live resin cartridges, Transpring’s ceramic heating elements are designed with the end user in mind.

Conclusion

The heating element is the heart of every cannabis vape. It determines how the oil is vaporized, how the flavor tastes, and how safe and enjoyable the overall experience is. From simple cotton wicks to advanced ceramic cores, the evolution of heating elements reflects the industry’s pursuit of better performance and higher safety standards.

Transpring’s decision to develop and manufacture our own ceramic heating elements demonstrates our long-term commitment to innovation. By controlling formulas, structure, and production processes, we provide solutions tailored to the diverse needs of the cannabis market. For brands looking to deliver consistent quality and consumers seeking the best vaping experience, the heating element makes all the difference—and Transpring continues to lead the way in ceramic core technology.